The Versatile Applications of Stainless Steel Across Various Industries

Stainless steel, known for its exceptional corrosion resistance and strength, is one of the most versatile and widely used materials in the modern world. Its unique properties make it an indispensable component in a vast array of industries, from construction and medical equipment to kitchenware and transportation. This article explores the diverse applications of stainless steel and how it contributes to the functionality and durability of products and infrastructure across different sectors.

1. Construction and Architecture

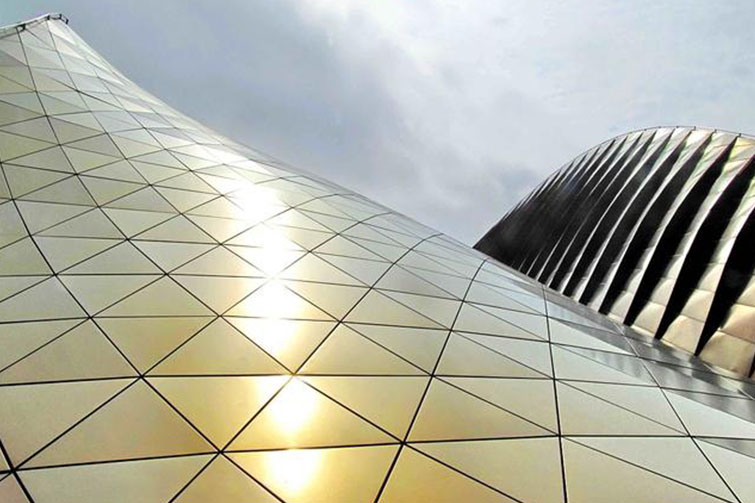

Stainless steel plays a crucial role in construction and architecture, offering both aesthetic appeal and structural integrity:

Building Facades and Cladding: Stainless steel is often used for building facades and cladding due to its ability to withstand harsh weather conditions and its sleek, modern appearance. Iconic structures like the Chrysler Building in New York and the Atomium in Brussels showcase the aesthetic potential of stainless steel in architecture.

Structural Components: The material's high strength-to-weight ratio makes it ideal for structural applications, including beams, columns, and load-bearing components in buildings and bridges. Its durability ensures long-lasting performance, reducing maintenance costs over time.

Interior Design: Stainless steel is also popular in interior design for handrails, countertops, and decorative elements. Its clean, reflective surface adds a contemporary look to any space.

2. Automotive and Transportation

In the automotive and transportation industries, stainless steel is valued for its durability and resistance to corrosion:

Exhaust Systems: Stainless steel is commonly used in exhaust systems due to its ability to resist the corrosive effects of exhaust gases and high temperatures. This extends the lifespan of the system and reduces the need for frequent replacements.

Automotive Body Parts: Some high-end vehicles feature stainless steel body parts that not only provide a premium finish but also enhance the vehicle's resistance to impact and corrosion.

Railway and Marine Applications: Stainless steel is essential in railway and marine applications for its durability and resistance to rust, which is crucial in harsh environmental conditions. It is used in train carriages, shipbuilding, and components exposed to saltwater.

3. Medical and Healthcare

The medical and healthcare sectors rely heavily on stainless steel for its hygienic properties and ability to withstand sterilization processes:

Surgical Instruments: Stainless steel is the material of choice for surgical instruments due to its non-reactive surface and ability to maintain sharpness. It can be repeatedly sterilized without degrading, ensuring patient safety.

Medical Implants: Biocompatibility is a key property of stainless steel, making it suitable for medical implants such as orthopedic screws, plates, and joint replacements. Its strength and resistance to bodily fluids ensure long-term functionality.

Hospital Equipment: From bed frames to IV stands, stainless steel is widely used in hospital equipment for its ease of cleaning and resistance to bacteria, helping to maintain a sterile environment.

4. Food and Beverage Industry

Stainless steel is indispensable in the food and beverage industry, where hygiene and contamination resistance are paramount:

Kitchen Equipment and Appliances: Commercial kitchens and household appliances often use stainless steel for countertops, sinks, refrigerators, and utensils. Its non-porous surface prevents the absorption of food particles and makes cleaning easy.

Food Processing Equipment: In food processing plants, stainless steel is used for tanks, conveyors, and machinery parts that come into contact with food. Its resistance to corrosion from acidic and alkaline foods ensures product safety and longevity of equipment.

Beverage Production: Stainless steel tanks and pipelines are used extensively in breweries, wineries, and dairy production for their ability to maintain the purity of the liquids and prevent contamination.

5. Energy and Power Generation

In the energy and power generation sectors, stainless steel's strength and resistance to extreme conditions are critical:

Nuclear Power Plants: Stainless steel is used in nuclear reactors and related components due to its ability to withstand high radiation levels and extreme temperatures without corroding or degrading.

Renewable Energy: Wind turbines and solar panels often incorporate stainless steel components for their structural strength and resistance to environmental factors such as salt spray and high humidity.

Oil and Gas Industry: In the oil and gas industry, stainless steel is used for pipelines, offshore platforms, and processing equipment. Its ability to resist corrosion from oil and gas products and withstand high pressures is vital for safe and efficient operations.

6. Household and Consumer Goods

Stainless steel is a staple in household items and consumer goods for its durability and sleek appearance:

Cookware and Cutlery: Stainless steel is widely used in cookware and cutlery due to its resistance to heat and corrosion. It maintains its luster and does not react with food, making it ideal for cooking and dining.

Home Appliances: Major appliances such as refrigerators, dishwashers, and washing machines often feature stainless steel components for their modern look and long-lasting performance.

Decorative Items: Stainless steel is also popular in home decor, from furniture to fixtures, adding a touch of elegance and modernity to living spaces.

7. Aerospace and Defense

In aerospace and defense, stainless steel is valued for its ability to withstand extreme conditions:

Aircraft Components: Stainless steel is used in various aircraft components, including structural parts and engine components, for its strength, heat resistance, and ability to perform under high stress and pressure.

Defense Equipment: The defense sector uses stainless steel for vehicles, weapons, and protective gear, where durability and resistance to harsh environments are critical.

Conclusion

Stainless steel's versatility and unique properties make it a crucial material across a multitude of industries. Its resistance to corrosion, strength, aesthetic appeal, and ability to withstand extreme conditions ensure its continued prominence in applications ranging from construction and automotive to medical and household products. As technology advances and the demand for durable, high-performance materials grows, stainless steel will undoubtedly continue to play a pivotal role in shaping the future of various sectors.